Breathe For Me: About the film

–

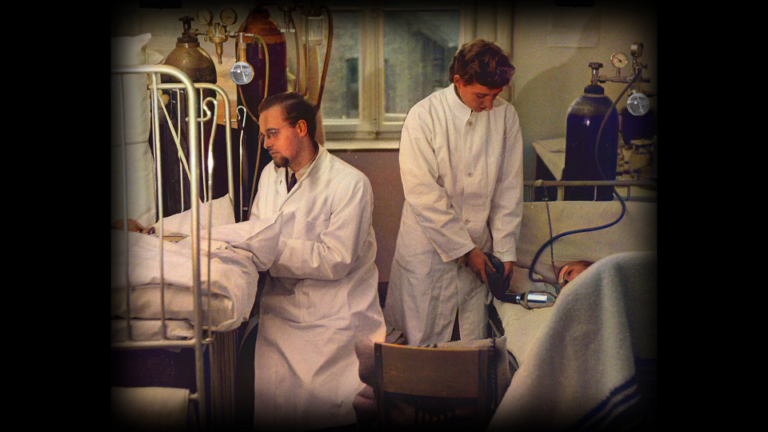

Stills from the film (1)

- Design and build a ventilator in 10 days? That has to be impossible. I agreed of course, as you do.

2) COVID spreads across Italy causing chaos. We can see it coming. Now it hits the UK in a major way.

3) We know what happened. However, take yourself back to March 2020 and the future situation was far from clear.

4) Interview in London.

5) Why were we challenged to do this? We must go back to the 90’s when I was challenged to think about a simple ultra-economical ventilator that would fit in a backpack, including the oxygen for it, by two Australian doctors who wanted to parachute down to patients in remote areas to stabilise them for up to 24h before air recovery.

6) Most components for everything, including ventilators, are made in China. All supply chains had failed. This machine will therefore NOT resemble conventional ICU ventilators.

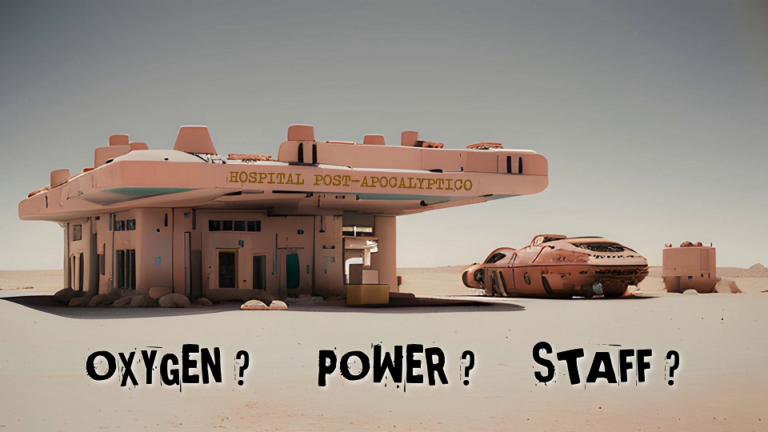

7) Will gas supplies fail? Will we have reliable power? Will there be any ICU staff to run it?

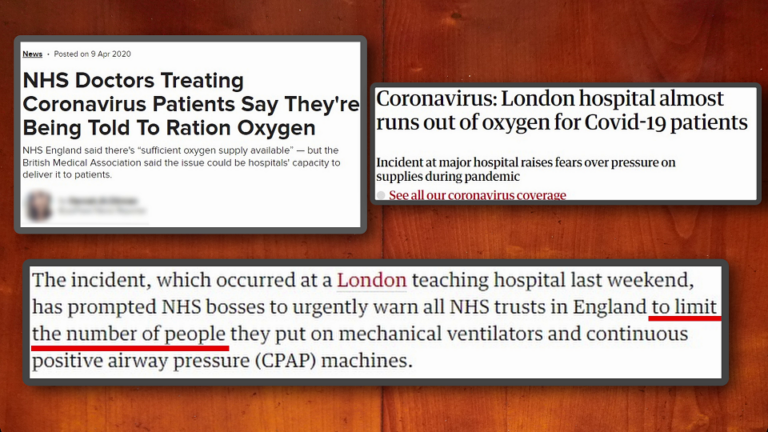

8) Such issues were not imaginary, they were very real.

9) Relatives of patients in India had to source their own oxygen for their relatives. This is an oxygen cylinder queue.

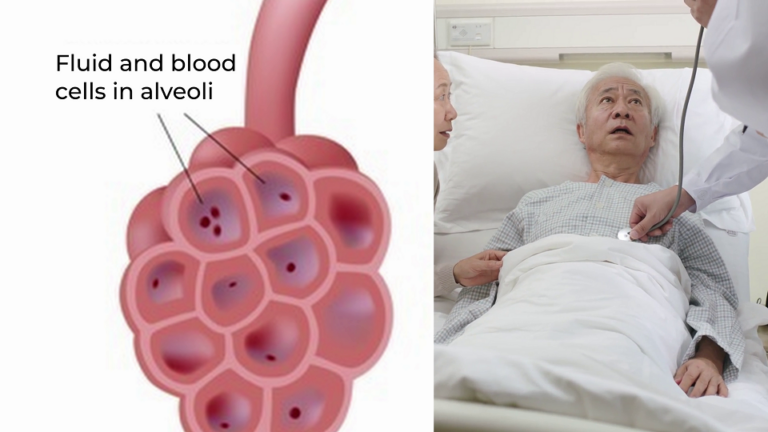

10) The virus damages the lungs.

11) Ventilators gradually developed from attempts at resuscitation, often in cases of drowning.

12) Some early methods of resuscitation were more effective than others. Air is being blown into this patient, just the wrong end of the patient!

13) Some ventilators contain mechanically operated bellows. Bellows as a concept had been around for centuries, commonly used by blacksmiths.

14) Ventilation of the lungs by relays of medical students squeezing rubber bags 24h a day by hand during 1952 polio outbreak in Copenhagen, Denmark. This was the origin of the first Intensive Care Units and after this outbreak early lung ventilator designs appeared.

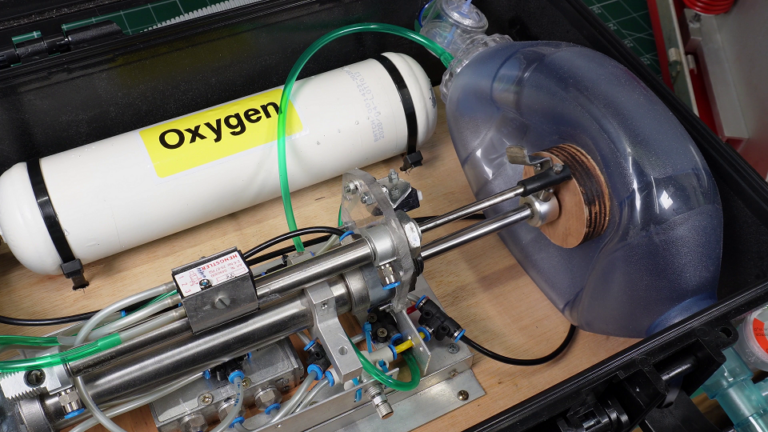

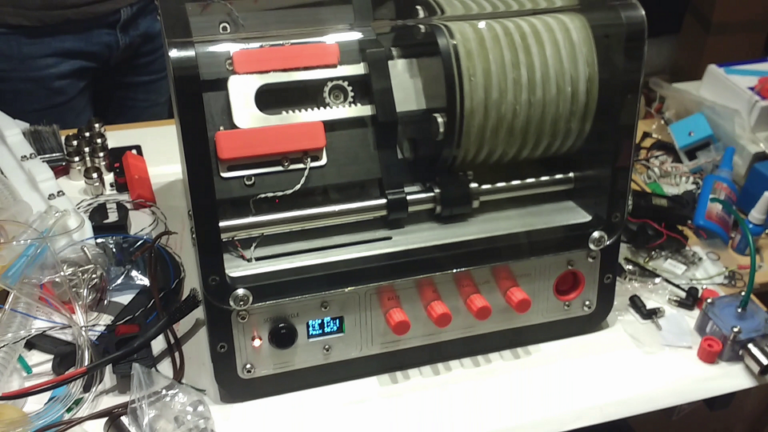

15) Resuscitation bag squeezer ventilators. Many similar designs appeared during COVID. Here is the one I made in 2008 in response to the personal challenge by the Australian doctors. It did use very little oxygen. It was probably why I was contacted this time around. Unfortunately, for COVID, more sophisticated machines than these would be required.

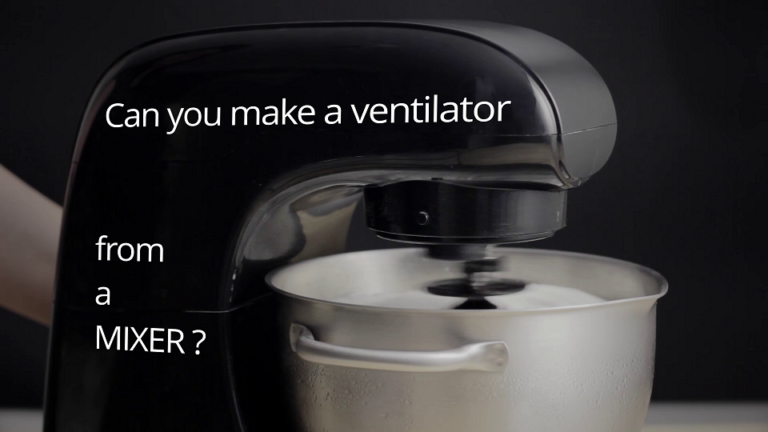

16) Here is one resuscitation bag squeezer design that appeared online during 2020. I have recreated it for this film. The food mixer vent.

Stills from the film (2)

17) Here it is. It does work to some extent but not good enough for COVID patients. Very imaginative idea though nevertheless. I recreated some other home-built designs for this film, including one which was made for $32 from scrap and kept a man with a spinal injury alive for many years in China. However, he had normal lung tissue but could not breathe in or out. With COVID the lungs themselves become damaged and so more sophisticated ventilators are required.

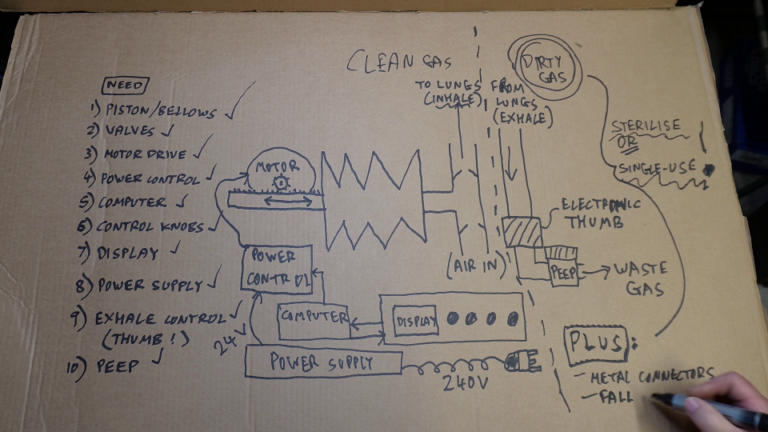

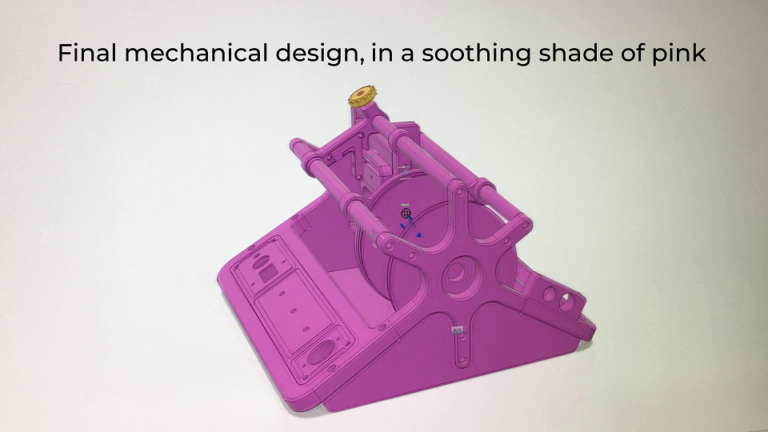

18) Design plan for our 2020 machine. The CoronaVent.

19) Interview at a small company making basic ventilators for use in very harsh environments in Africa. He had a number of insights from the African experience, where oxygen, power and staff are always in short supply. That is their normal situation.

20) Charitable donations of totally unsuitable overcomplicated equipment are an ongoing issue in Africa. These gloves had turned to slime in the unforgiving heat and were completely unusable.

21) Most ICU ventilators consume huge quantities of oxygen as normally it is cheap and plentiful. Our design going to have to be far more economical with oxygen.

22) It certainly doesn’t look like a conventional ICU ventilator – as promised.

23) Emergency metalworking advice from an engineer friend at 1:00 am. Heating metal rods to glowing red in his Anthracite-fuelled stove. This is the finest form of Welsh coal which used to power the British Navy fleet and burns very hot.

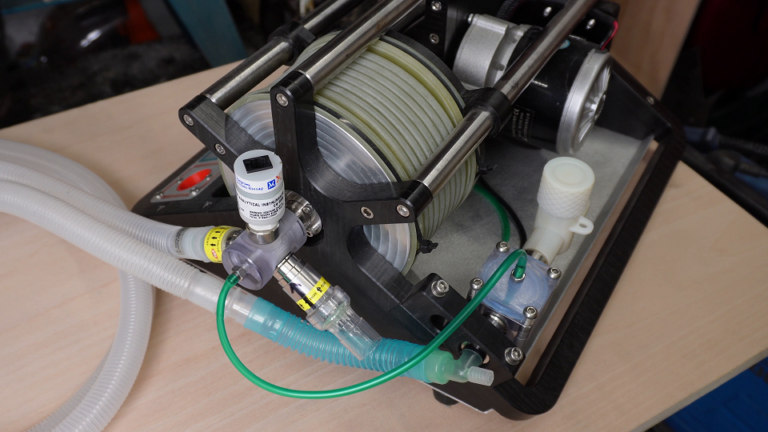

24) Day 9. Minimal sleep. Everyone very tired.

25) Version 1 of the CoronaVent. Designed and built in 10 days.

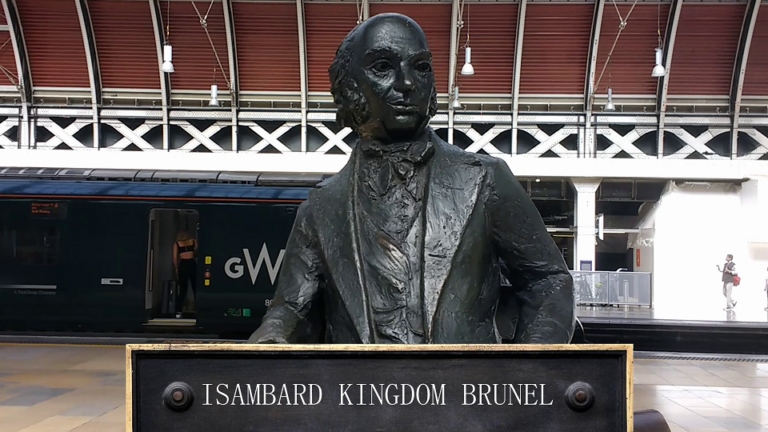

26) Britain’s most famous engineer. Statue at Paddington Station, London.

27) Version 2 of our design. The rules kept being changed. It had to be waterproof – so we made it waterproof, among many other changes. The design is still unusual as we also had to develop workarounds for key parts that were simply unavailable.

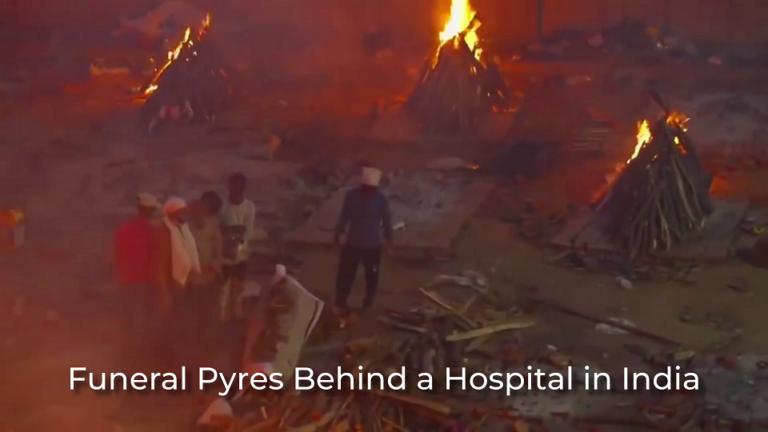

28) Could things become apocalyptic? Well, in some places it certainly looked that way.

29) One big issue to note for the future is that when offered something for free, it is human nature to demand (as the minimum acceptable specification) the nicest most well-featured ventilator possible. This means in reality you will then receive nothing. If offered a free car for example, would you initially ask for a 1970’s VW Beetle? It remains one of the most user-serviceable car designs ever made and in a crisis situation might be a much better choice than a Lamborghini.

30) This was a real issue during the pandemic as the minimum specification requirements kept changing with additional features being added to the list all the time. There must be some agreement on such matters before the next one.

31) With the benefit of hindsight, other methods to support breathing that did not involve full ICU mechanical ventilation (luckily) proved to be very effective in many patients. This saved ICU’s, not entirely but to some extent, from being overwhelmed. This was only by good fortune however. A future virus might not be as amenable to such treatments.

32) In the well-known adventure movie starring Harrison Ford, everyone can now be reassured that we have top people working on this, TOP people. This may or may not be the case. Are we now better prepared for another pandemic? Never assume anything.

Until next time…………..